Optimized Cooling Block

Introduction

Traditional hot aisle/cold aisle HVAC air cooling methods have long been used in data centers to manage heat generated by servers. However, as next-generation applications drive computing systems to higher power densities, traditional air cooling has become increasingly inefficient and unable to meet performance and energy demands. This challenge underscores the need for more effective and sustainable cooling technologies. As a result, data centers are shifting toward advanced liquid cooling solutions, including fully liquid systems, hybrid liquid–air configurations, and liquid-to-air designs. These innovations aim to improve thermal efficiency, reduce energy consumption, and enable the continued scaling of high-performance computing systems.

Goal

To design and optimize a unique liquid cooling solution for the ever growing need within data centers.

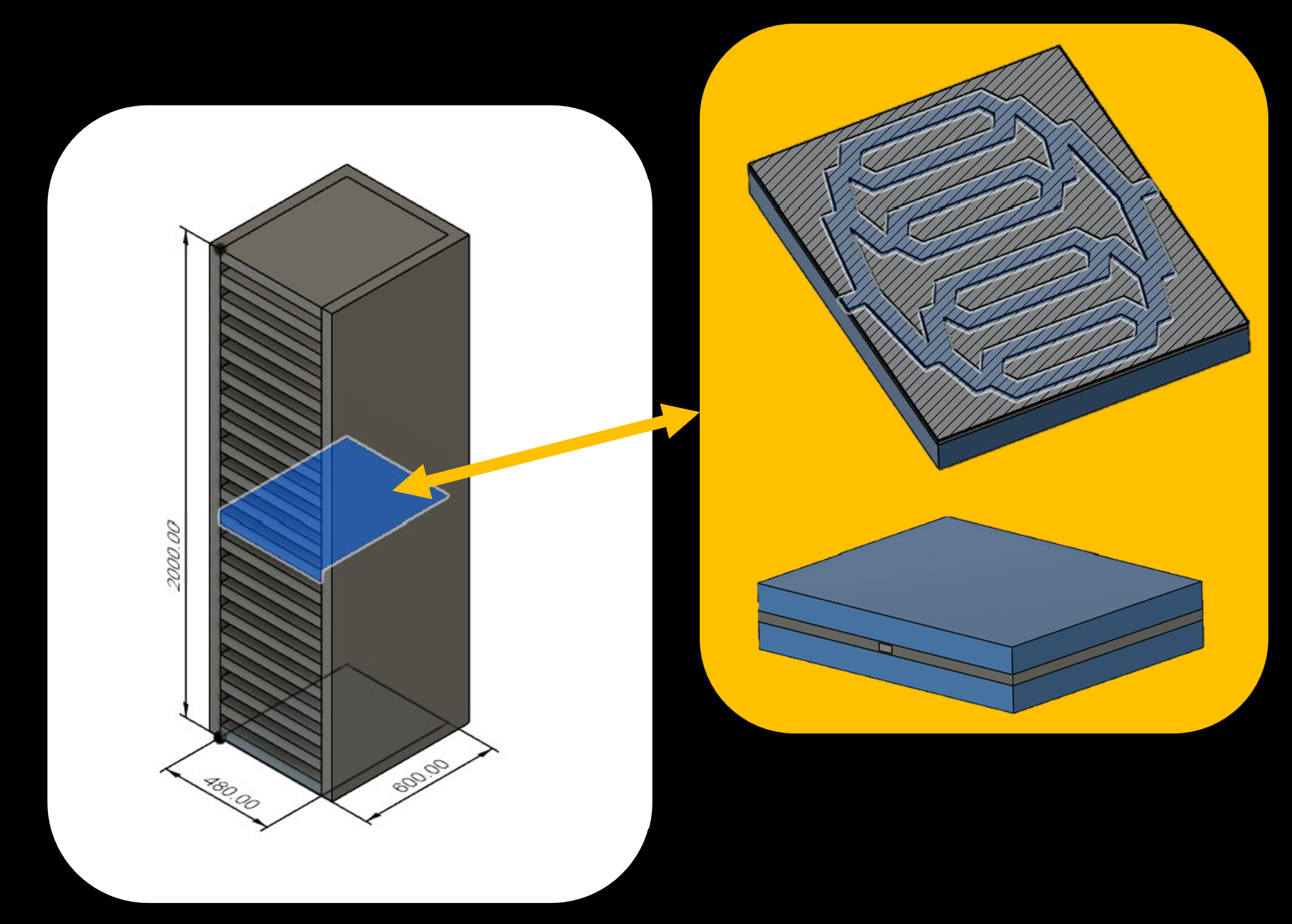

Problem description

The proposed system design introduces a heat exchanger plate positioned between two 1U server racks to efficiently manage thermal loads within the server stack. Each 1U server has dimensions of 50×480×600 mm and produces a heat input of 1150 W. The heat exchanger plate, measuring 20×480×600 mm, is designed to circulate coolant at a mass flow rate of 0.3 kg/s, effectively transferring heat away from the servers. This modular configuration allows for scalable implementation across the entire rack, providing an efficient and compact cooling solution for high-density data center environments.

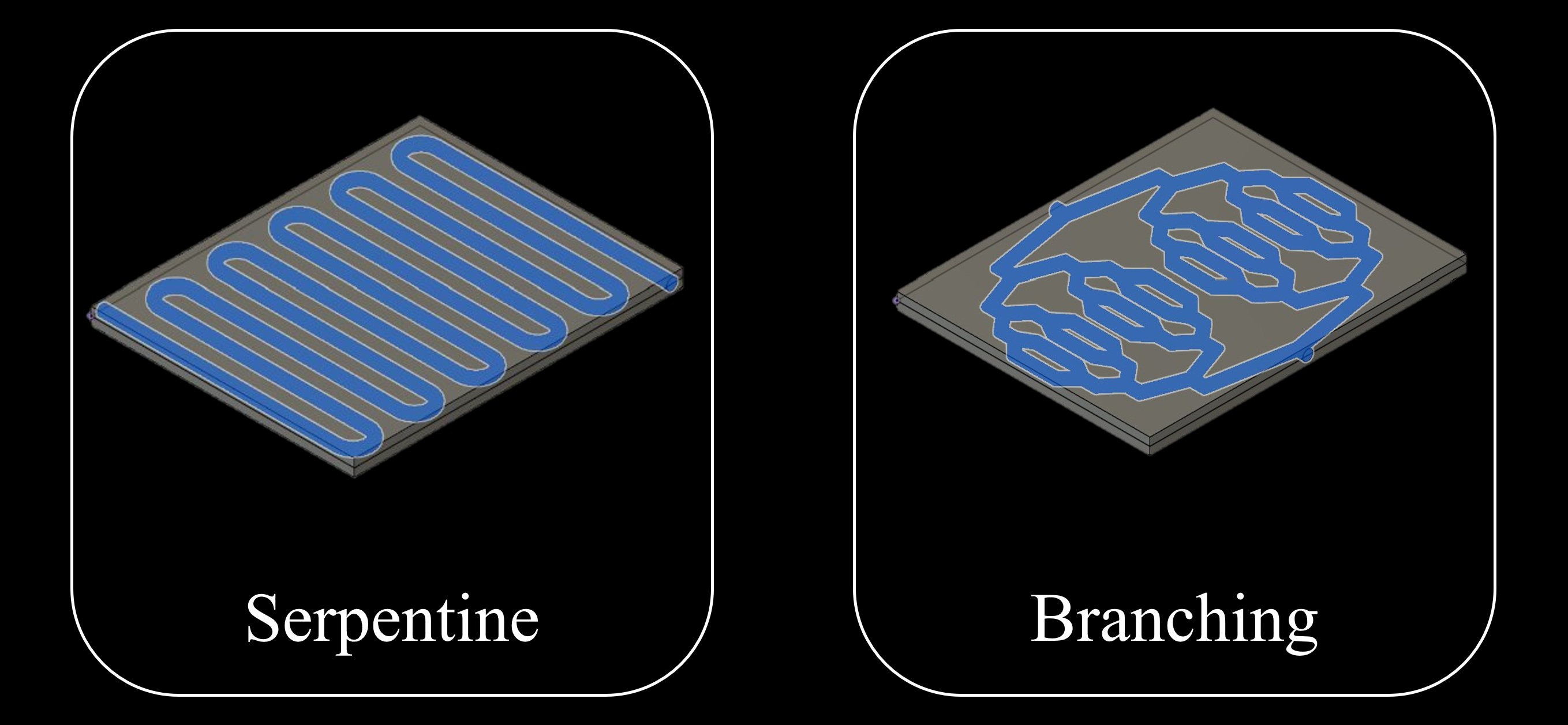

Inital Simulation

To determine the best base geometry for our heat exchanger, we performed initial simulations comparing two designs, the serpentine and the branching configurations. These tests helped us evaluate the trade-offs between heat transfer performance and pressure loss, guiding our selection of the most efficient geometry for further development.

Serpentine

- Pros:

- Higher heat transfer efficiency

- Cons:

- Higher pressure loss

- Unoriginal design

Branching

- Pros:

- Lower pressure loss

- Unique and efficient design

- Cons:

- Concern for dead spots

- Lower heat transfer rate

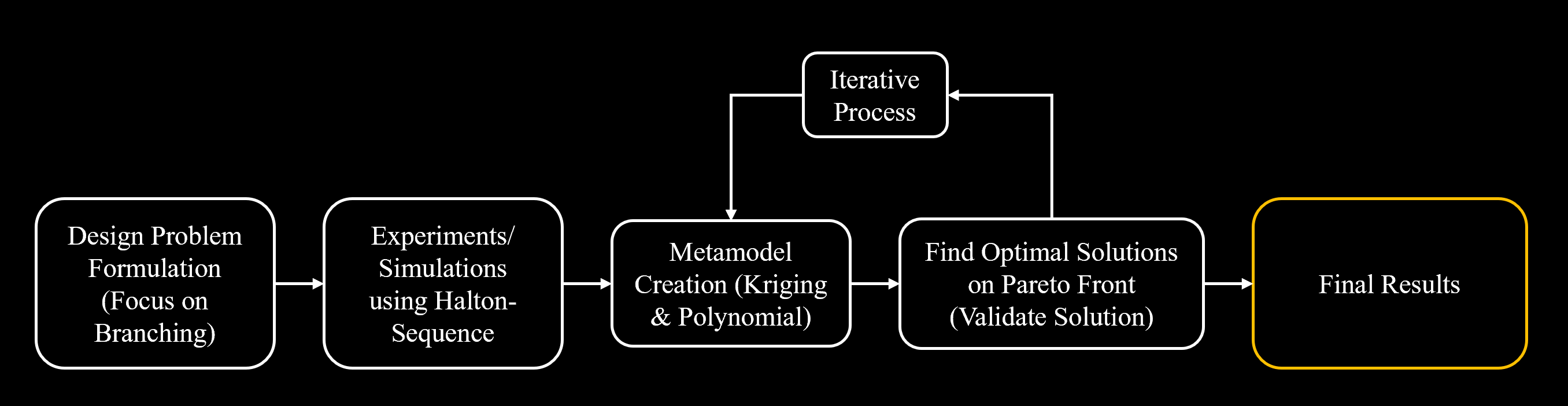

Design Method

Problem Formulation

- Minimize:

- Pressure Loss (Inlet to Outlet) [Pa]

- Average Surface Temperature [K]

- Maximize:

- Heat Transfer (Outlet) [W]

- Subject to:

- Given Geometry (H×W×D): 20×480×600 mm

- Given Mass Flow Rate: 0.3 kg/s

- Design Variables & Bounds:

- Channel Width: 14–30 mm

- Number of Bifurcations: 2, 3, or 4

Experiment Setup

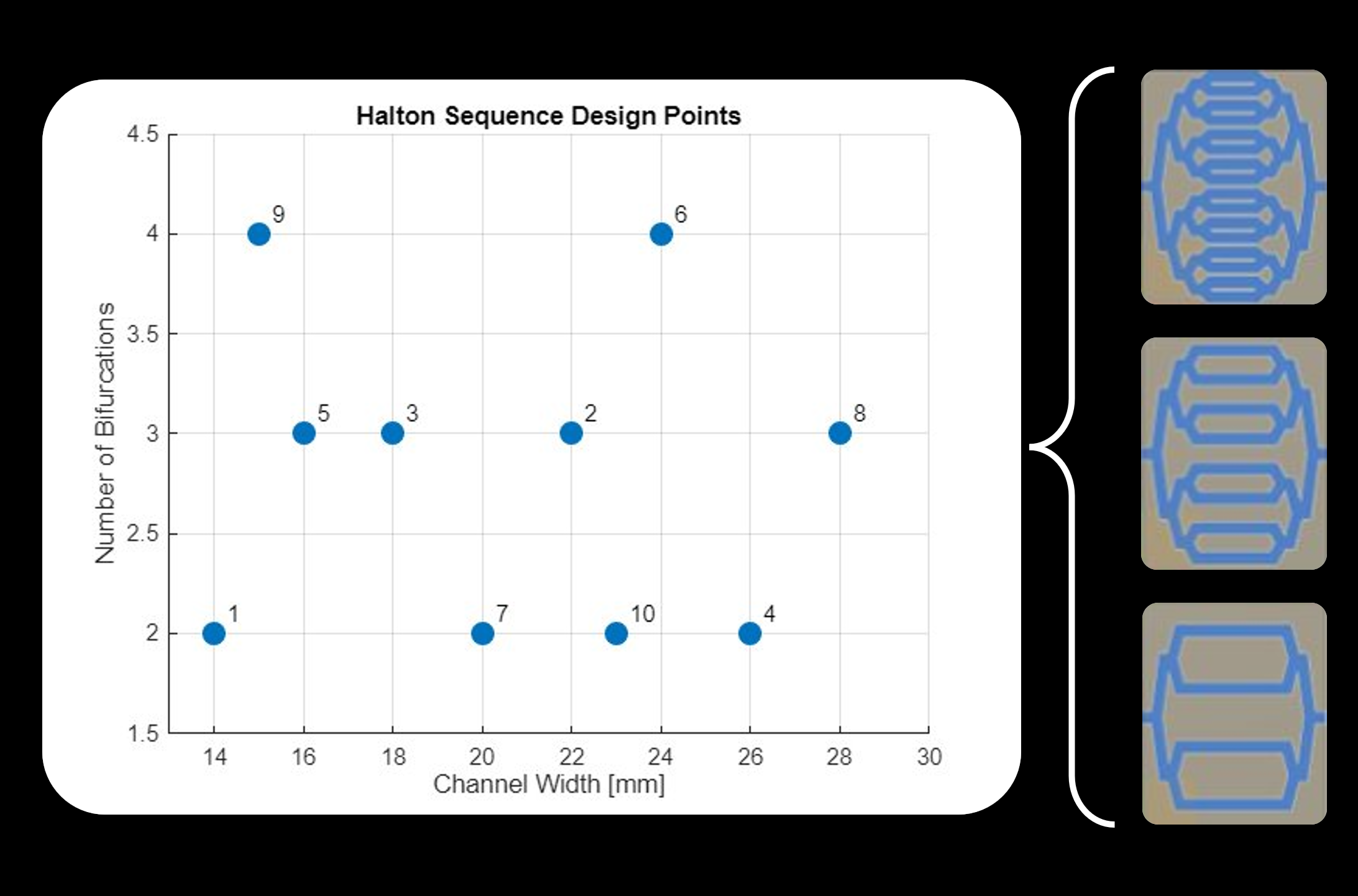

To sample the design space efficiently, a Halton sequence was used over the two primary variables: channel width (14–30 mm) and number of bifurcations {2, 3, 4}. Ten quasi‑random design points were generated to avoid clustering and ensure good coverage. The scatter plot labels correspond to the rows in the accompanying table. From these candidates, three base designs were selected to span narrow, medium, and wide channel widths.

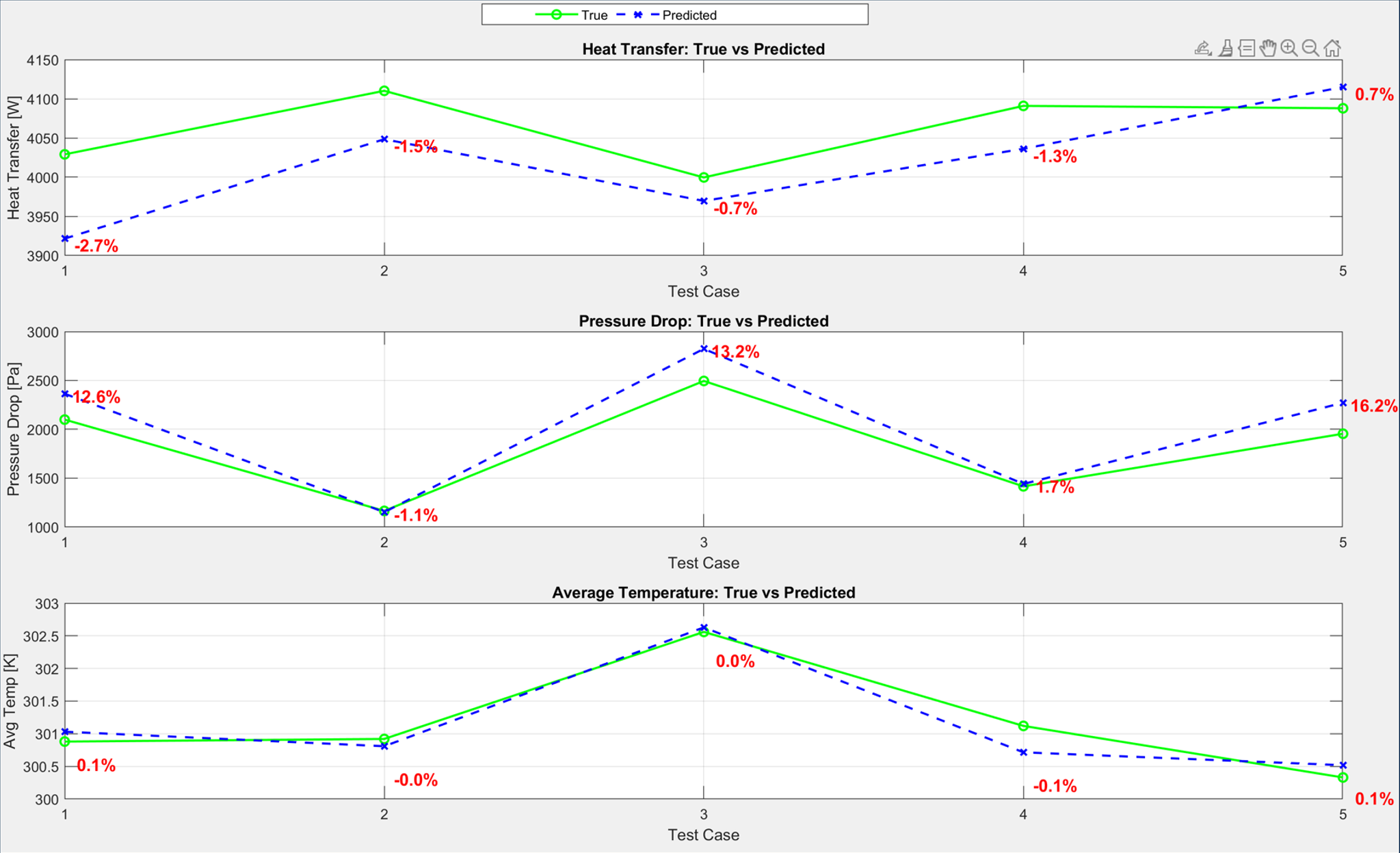

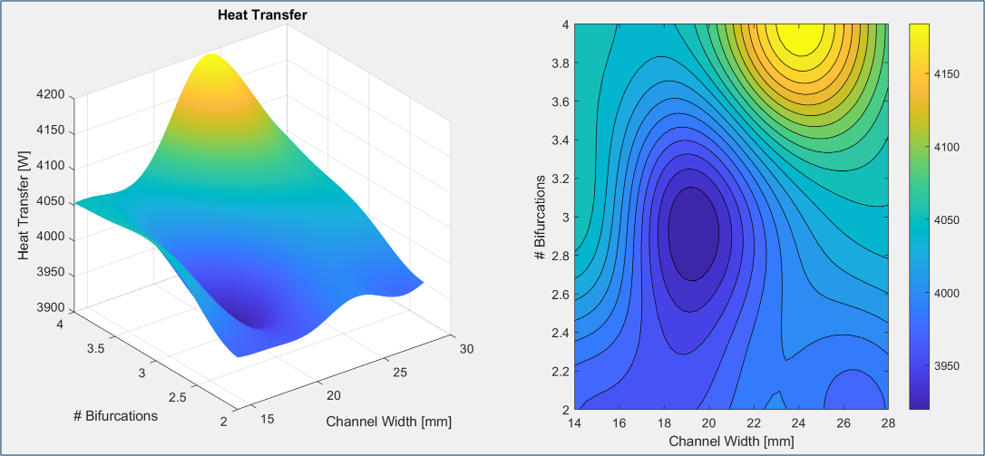

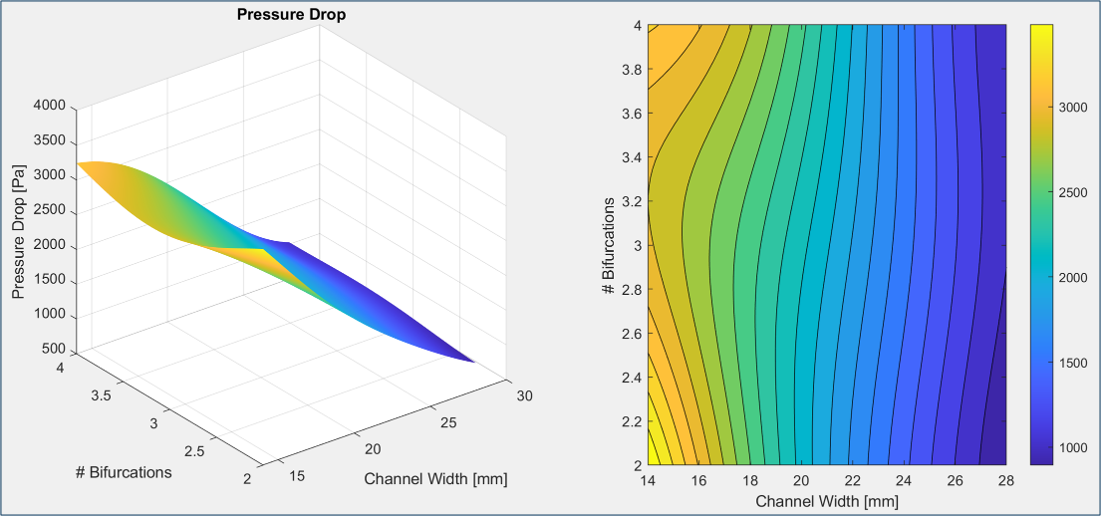

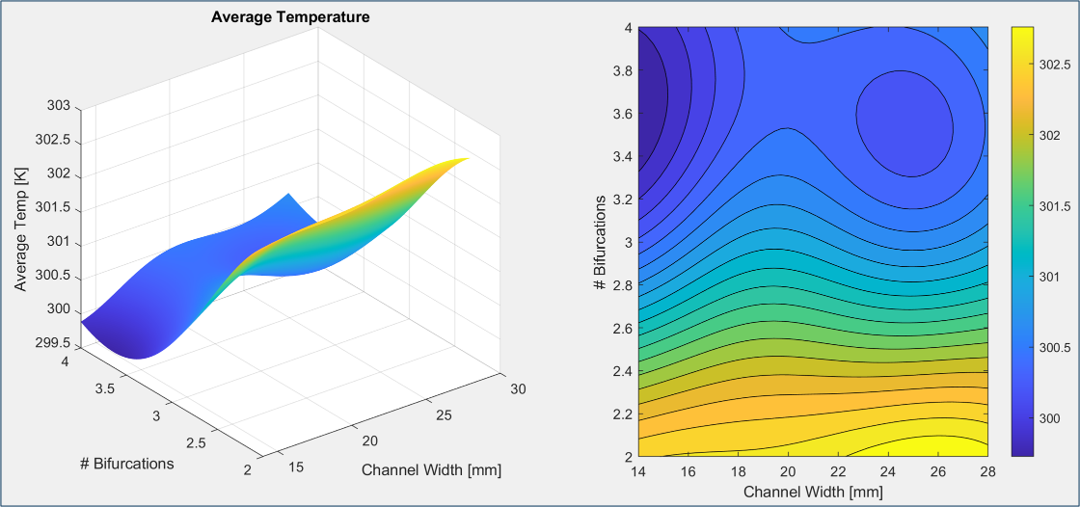

Trained Metamodel

The results of the trained metamodels can be seen below for the three objectives.

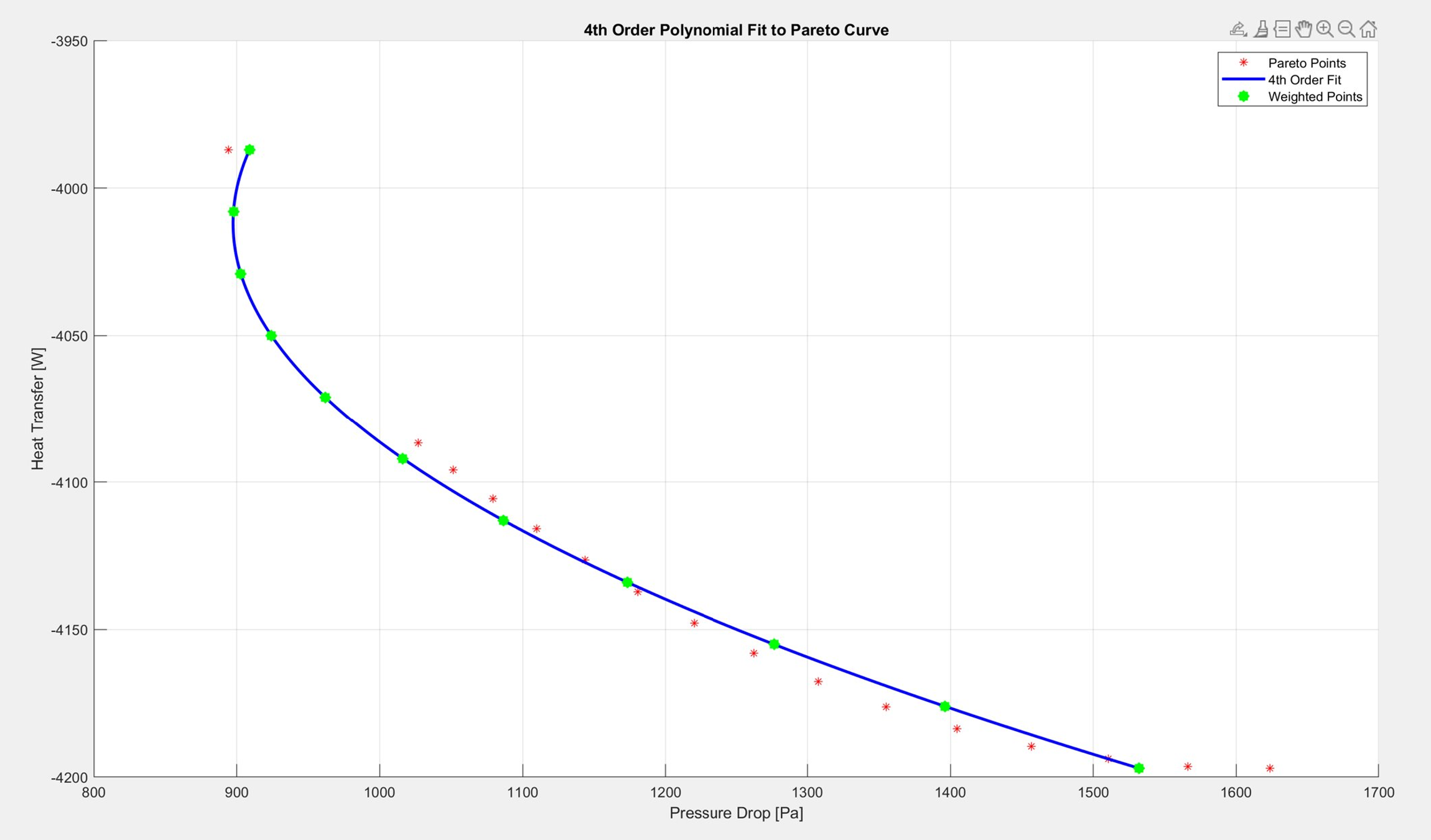

Pareto Front

The chart shows the trade-off between pressure drop and heat transfer; the blue 4th‑order curve approximates the efficient Pareto boundary defined by the red points.

Optimal Result

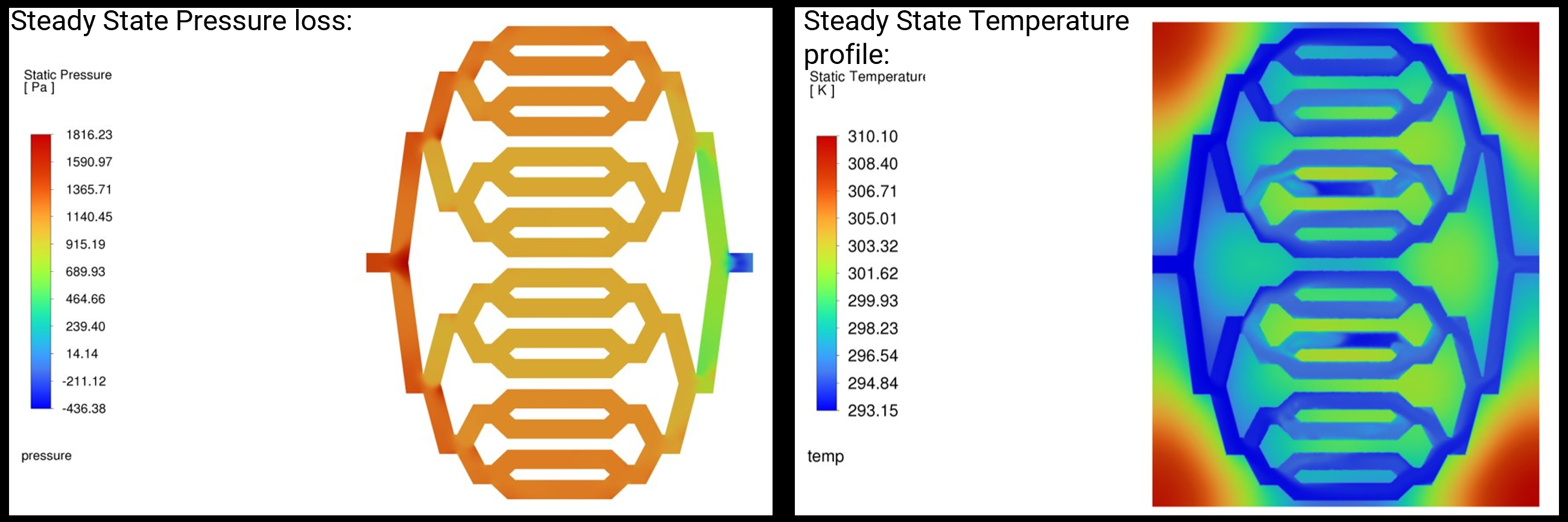

Using a 50/50 weighted‑sum across objectives yields a balanced design with 4 bifurcations and a 28 mm channel width. This solution achieves Heat Transfer of 4139.73 W with a Pressure Loss of 1071.38 Pa, representing a practical trade‑off between performance and pumping cost.

Why Trust the Metamodel?

We validated the metamodel against additional, hold‑out simulations and found that predictions closely track the true trends across all three objectives. Heat transfer and average temperature show small percentage errors, while pressure‑drop deviations are larger at extremes but preserve ranking—sufficient for reliable design selection on the Pareto front.