Coffee Filter Holder

Introduction

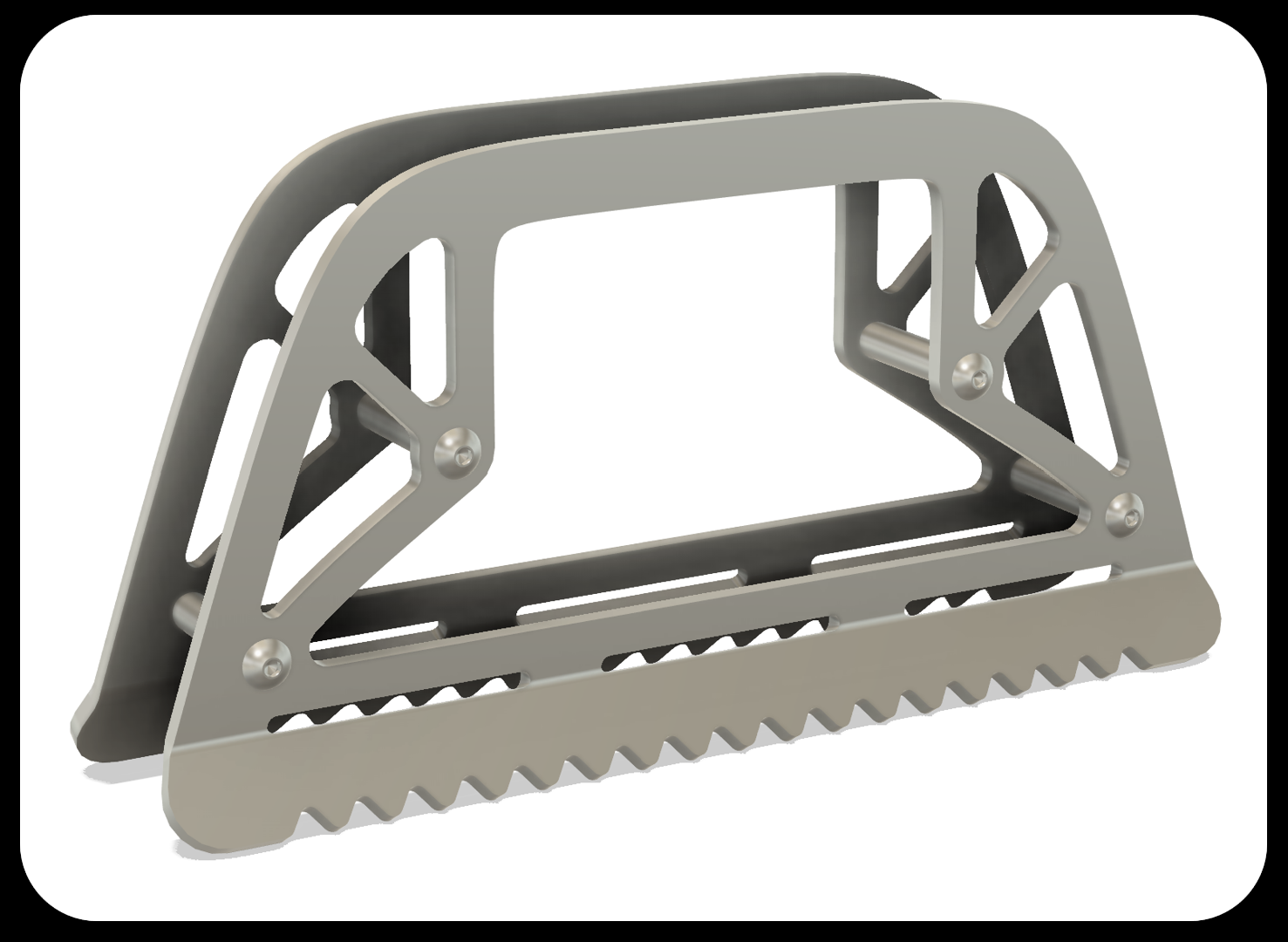

Coffee filter holder design utilizing BESO (Bi-directional Evolutionary Structural Optimization) topology optimization.

Design Methodology

Defining the Domain

For this project, the domain was defined by measuring the dimensions of the coffee filter and assigning a length and width guided by the golden ratio.

Defining Loads and Boundary Conditions

The loads were applied at two different locations on the domain. To maintain a simple design, the points supporting the coffee filters also serve as the connection points between the two faceplates. Once again, the golden ratio was used as an initial guide for load placement. The boundary conditions were defined as fixed along the bottom edge.

BESO Results

The BESO algorithm was used primarily to generate an initial design concept. Many of the early iterations resulted in geometries that were unmanufacturable due to extremely small feature sizes. Since the goal was to create a design suitable for sheet metal fabrication using water-jet cutting, significant refinement was required. After multiple BESO runs, a configuration was selected that could realistically lead to a manufacturable product. Given that the load (a stack of coffee filters weighing less than 100 grams) is minimal, using BESO for structural optimization is somewhat excessive. Therefore, visual appeal played a role in selecting the final baseline topology.

Refinement

Fusion 360 was used to convert the 2D output into a manufacturable 3D design. The cross-section was imported, the edges were rounded, and holes were added to accommodate the fasteners. A flared base was incorporated to ensure stability and prevent tipping. Relief cuts were added along the bend lines to ensure consistent, accurate bends.

Materials

- 1/8 inch thick sheet metal

- 8-32 stainless steel standoffs

- 8-32 stainless steel fasteners

Results

coming soon...